SEARCH

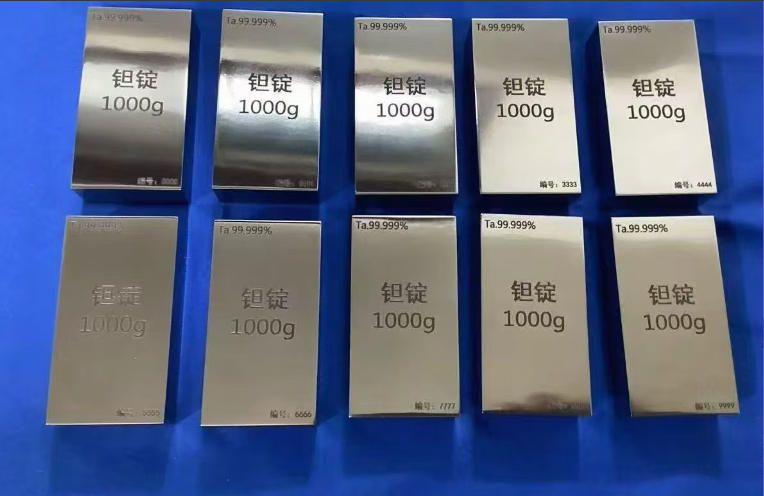

For industries that demand uncompromising performance in extreme environments, tantalum ingots stand as a benchmark of reliability and innovation. As a critical raw material, our high-purity tantalum ingots (99.999% purity) deliver exceptional material properties that solve engineering challenges across aerospace, electronics, chemical processing, and medical sectors.

1. Unmatched Corrosion Resistance Tantalum is nearly immune to attack by most acids, including hydrochloric, nitric, and sulfuric acid, even at high temperatures and concentrations. Unlike stainless steel or titanium, it forms a dense, self-healing oxide layer on its surface, which acts as a permanent protective barrier. This makes our tantalum ingots the ideal choice for chemical processing equipment, reactor liners, and corrosion-resistant components where durability is non-negotiable.

2. Exceptional Thermal & Electrical Performance With a melting point of 2996°C — one of the highest among all metals — tantalum retains its structural integrity under extreme heat. It also boasts excellent thermal conductivity and a low coefficient of thermal expansion, ensuring dimensional stability in high-temperature applications such as aerospace engine components and nuclear reactor parts. For electronics, its high dielectric constant and capacitance stability make it a cornerstone material for high-performance capacitors used in smartphones, medical devices, and military hardware.

3. Biocompatibility & Medical Grade Purity Tantalum is completely non-toxic and biologically inert, meaning it integrates seamlessly with human tissue without triggering rejection or inflammation. Our 99.999% pure tantalum ingots are the material of choice for orthopedic implants, dental fixtures, and surgical tools, where biocompatibility and corrosion resistance are life-critical.

4. High Strength-to-Weight Ratio Despite its impressive density, tantalum offers an excellent strength-to-weight ratio that outperforms many traditional metals. This makes it a lightweight yet robust solution for aerospace and defense applications, where reducing weight without compromising performance is a top priority.

5. Purity-Driven Consistency Our tantalum ingots are produced using advanced electron beam melting and vacuum arc melting technologies, ensuring 99.999% purity with minimal trace impurities. This level of consistency guarantees predictable material behavior, reducing production risks and ensuring your components meet the most stringent industry standards.

Tailored Solutions: We offer custom sizes, purity levels, and processing options to meet your exact specifications, from small research batches to large industrial orders.

Quality Assurance: Every ingot undergoes rigorous testing, including chemical analysis and mechanical property verification, to ensure compliance with ASTM, ASME, and ISO standards.

Global Supply Chain: With reliable production capacity and worldwide logistics, we ensure on-time delivery to keep your projects on schedule. --- Ready to elevate your next project with the unmatched performance of tantalum? Our team of material science experts is here to help you select the right grade, size, and processing for your application.

Contact us today to request a quote or technical consultation — let’s turn your engineering vision into reality.