SEARCH

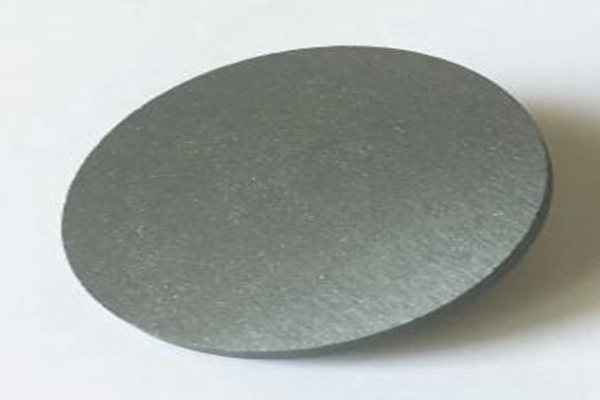

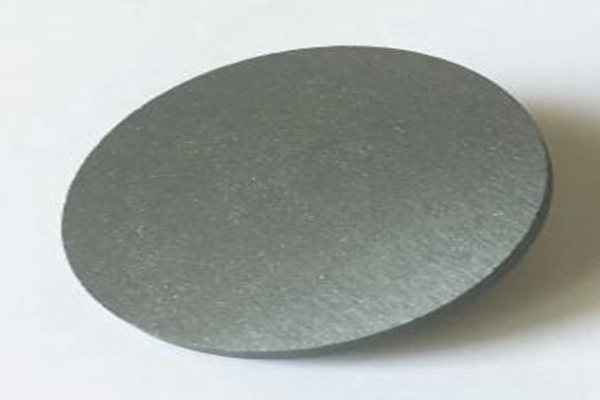

99.5% chromium targets are essential materials in the thin-film deposition industry, offering a combination of high purity and excellent material properties for a wide range of applications.

Electronics and Semiconductors: Chromium layers serve as barrier layers, conductive paths, and adhesion layers in the fabrication of integrated circuits and electronic components.

Automotive Industry: Used in decorative and protective coatings for automotive parts, including trim, wheels, and other components exposed to the environment.

Data Storage: Thin films of chromium are used in magnetic media for data storage applications due to their magnetic properties.

Deposition Conditions: The quality of the chromium film can be influenced by the deposition parameters, including temperature, pressure, and deposition rate. Optimizing these conditions is crucial for achieving the desired film properties.

Substrate Preparation: Proper substrate preparation is essential to ensure good adhesion of the chromium film. Surface cleaning and etching may be required prior to deposition.

Environmental and Health Safety: Chromium and its compounds, particularly hexavalent chromium, can pose environmental and health risks. Safe handling practices and appropriate protective equipment are necessary to mitigate these risks.

PHONE

ADDRESS

Gaoya Village Industrial Park, Banyu Town, Baoji City, Shaanxi Province, China

English

English русский

русский