SEARCH

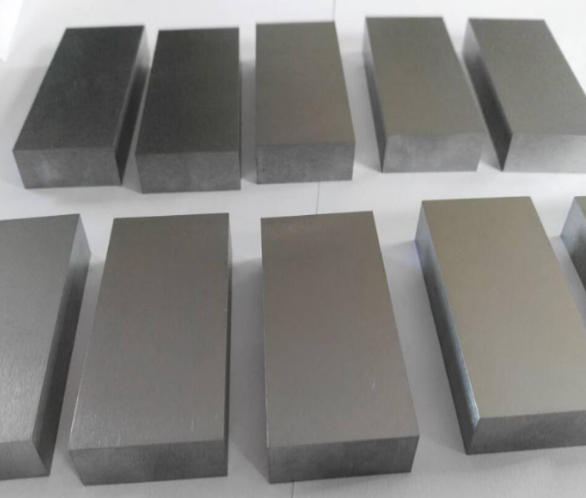

As a strategically critical refractory metal, niobium ingots stand out as a cornerstone material in high-tech and heavy industries worldwide. With exceptional physical and chemical properties, these ingots serve as the raw material for manufacturing high-performance components that power aerospace, energy, electronics, and infrastructure projects. At Xi’an VIKASI, we specialize in producing high-purity niobium ingots tailored to meet the stringent demands of global advanced manufacturing—delivering reliability, durability, and performance where ordinary metals fall short.

Niobium ingots’ unique combination of properties makes them irreplaceable in mission-critical applications, outperforming many other refractory metals in versatility and efficiency:

Exceptional High-Temperature Resistance: Boasting a melting point of over 2,468°C, niobium ingots maintain structural integrity and mechanical strength in extreme heat environments, surpassing the performance of conventional metals like steel and aluminum. This trait is indispensable for components exposed to high-temperature operations.

Superior Corrosion Resistance: Pure niobium ingots exhibit excellent resistance to corrosion by acids, alkalis, and harsh chemicals, as well as hydrogen embrittlement. This makes them ideal for use in aggressive industrial settings where material degradation is a major concern.

Outstanding Superconducting Properties: High-purity niobium ingots (99.8%+ purity) demonstrate remarkable superconducting capabilities at low temperatures, enabling energy-efficient performance in advanced electronic and medical devices. They are a key material for superconducting radiofrequency (SRF) cavities in particle accelerators and quantum computing systems.

Excellent Mechanical Workability: Despite their high melting point, niobium ingots offer good ductility and formability, allowing them to be processed into tubes, sheets, wires, and complex components through rolling, forging, and machining. This flexibility supports customized manufacturing for diverse industry needs.

Enhanced Alloy Performance: As a critical alloying element, niobium ingots significantly improve the strength, fatigue resistance, and weldability of high-strength low-alloy (HSLA) steels. Even small additions of niobium can reduce material weight by 10-20% while maintaining structural stability, contributing to global decarbonization goals.

Niobium ingots are integral to driving innovation and efficiency across a range of high-value sectors, addressing the most demanding application requirements:

Aerospace & Defense

The aerospace industry relies heavily on niobium ingots for manufacturing jet engine components, spacecraft structures, and thermal protection systems. Their ability to withstand extreme temperatures and pressure fluctuations ensures flight safety and fuel efficiency. Advanced niobium-based alloys are used in rocket nozzles and satellite components, where reliability in harsh space environments is non-negotiable. With our high-purity ingots, manufacturers can produce components that meet the strict standards of aerospace regulators worldwide.

Energy & Nuclear Engineering

In the energy sector, niobium ingots play a vital role in both conventional and renewable energy projects. They are used in nuclear reactor cores and cladding materials due to their high melting point and resistance to radiation damage. For renewable energy, niobium-alloyed steels are essential for offshore wind turbine structures, as they enhance fatigue resistance and durability in corrosive marine environments. Additionally, niobium ingots support hydrogen energy infrastructure by enabling the production of high-pressure pipelines that resist hydrogen embrittlement—critical for the global energy transition.

Electronics & Superconductivity

High-purity niobium ingots are the backbone of advanced electronic devices and superconducting technologies. They are processed into capacitors, high-frequency components, and SRF cavities for medical imaging equipment (such as MRI machines), particle accelerators, and quantum computers. The ultra-low electrical resistance of superconducting niobium reduces energy consumption by up to 50%, making it a preferred material for next-generation electronic systems.

Infrastructure & Automotive

Niobium ingots contribute to building stronger, more sustainable infrastructure and automotive components. In civil engineering, niobium-alloyed steels are used in bridges, rail systems, and high-pressure gas pipelines, as they enable thinner walls without compromising strength—reducing material usage and carbon emissions. For the automotive industry, these steels help reduce vehicle weight while maintaining crash safety, supporting global emissions reduction targets and improving fuel efficiency.

Medical Devices

With excellent biocompatibility, niobium ingots are used in manufacturing medical implants such as artificial joints, bone nails, and surgical instruments. The material’s resistance to corrosion and body fluid degradation ensures long-term safety and performance, making it a reliable choice for biomedical applications where patient safety is paramount.

At Baoji Aulister, we adhere to strict quality control standards throughout the production process, from raw material selection to vacuum arc melting and electron beam melting. Our niobium ingots are available in multiple purity grades to suit diverse applications:

Industrial Grade (98.6% purity): Cost-effective for nuclear reactor components, optical glass, and structural alloys.

High-Purity Grade (99.5%-99.7% purity): Ideal for aerospace superalloys, electronic capacitors, and precision instrumentation.

Ultra-High Purity Grade (99.8%+ purity): Essential for superconducting technologies, quantum computing, and particle accelerators.

We offer customized sizes and processing solutions, ensuring our niobium ingots seamlessly integrate into your production workflow. Backed by our 15+ years of(international trade) experience, we provide transparent pricing, reliable logistics, and full support for export compliance—helping you mitigate risks and optimize costs.

Whether you’re developing aerospace components, energy infrastructure, or advanced electronics, our high-purity niobium ingots deliver the performance and consistency your projects demand. Contact us today with your specifications, and our team of experts will provide a tailored quote and technical support to meet your needs. Let’s collaborate to turn your innovative ideas into reality with the power of niobium.

This is the first one.