SEARCH

Choosing the right material is critical for engineering success. In the world of high-performance metals, Titanium stands out, but it comes in two distinct forms: Commercially Pure (CP) Titanium and Titanium Alloys. Understanding their differences is key to selecting the optimal solution for your project’s demands of strength, corrosion resistance, and weight.

At Baoji Aulister, we specialize in the precision processing of both pure and alloyed titanium. This guide will help you navigate the choice and see why partnering with an expert processor is your ultimate advantage.

Commercially Pure (CP) Titanium is valued not for absolute purity, but for its unmatched balance in certain areas. It is graded (Grade 1, 2, 3, 4) based on increasing oxygen and iron content, which directly correlates to strength.

Key Advantages:

Superior Corrosion Resistance: It forms an incredibly stable, self-repairing oxide layer, offering exceptional resistance to chlorides, seawater, and a wide range of chemicals. Grade 2 is the most common and versatile grade.

Excellent Formability & Weldability: It is the most ductile and easiest to weld of all titanium forms, ideal for complex fabrications like heat exchanger shells, chemical processing tanks, and marine components.

Biocompatibility: Its inert nature makes CP Titanium (especially Grade 2 & 4) the standard for medical and dental implants, surgical tools, and body-contact devices.

Best For: Applications where corrosion resistance, formability, and biocompatibility are the top priorities, and extreme mechanical strength is secondary.

Titanium alloys are created by adding elements like Aluminum, Vanadium, Tin, and Zirconium. The most famous is Ti-6Al-4V (Grade 5), which revolutionized aerospace design.

Key Advantages:

High Strength-to-Weight Ratio: Titanium alloys can be twice as strong as common CP grades while maintaining the same famous lightweight property. This is the primary reason for its aerospace dominance.

Enhanced High-Temperature Performance: Alloys retain their strength at temperatures where CP titanium would soften, making them suitable for engine components and high-speed airframes.

Tailored Properties: Specific alloys are engineered for unique needs:

Ti-6Al-4V (Grade 5): The aerospace and medical implant workhorse.

Ti-6Al-4V ELI: An extra-low-interstitial version for superior fracture toughness in critical medical implants.

Beta Alloys: Offer high strength, excellent fatigue resistance, and improved cold formability.

Best For: Applications where maximizing strength, fatigue resistance, and performance under load or elevated temperature is critical.

Property | Commercially Pure Titanium (e.g., Grade 2) | Titanium Alloy (e.g., Ti-6Al-4V, Grade 5) | Industrial Implication |

Primary Strength | Moderate (Ultimate Tensile Strength: ~345 MPa for Gr2) | Very High (Ultimate Tensile Strength: ~895 MPa for Gr5) | Alloys allow for thinner, lighter, stronger structures. |

Corrosion Resistance | Excellent | Very Good (but can be slightly less than CP in some media) | CP Ti is the default for the most aggressive chemical environments. |

Formability & Weldability | Excellent | Good to Fair (requires more care and specific techniques) | CP Ti is preferred for complex, one-off fabrications. |

High-Temp Performance | Fair (usable up to ~300°C) | Good (usable up to ~450-500°C for short term) | Alloys are mandatory for jet engine and high-speed airframe parts. |

Cost (Relative) | Lower | Higher | The performance benefit of alloys justifies the cost in critical applications. |

Choosing between CP and alloyed titanium is just the first step. The real value is in obtaining material that is perfectly processed for your application.

Expert Guidance: We help you navigate the specifications (ASTM, AMS, ISO) to select the most cost-effective grade—whether it's Grade 2 CP Titanium sheet for an electrolyzer or Grade 5 Ti-6Al-4V bar for a landing gear component.

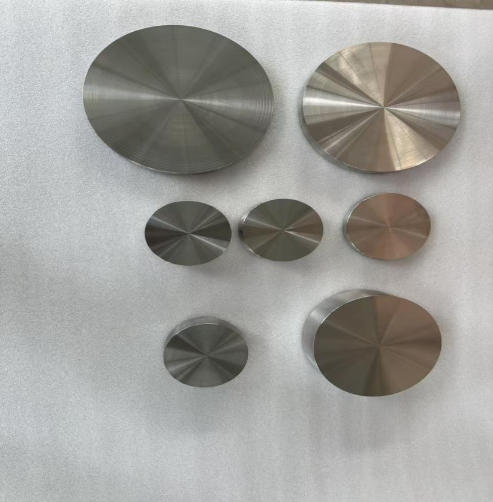

Precision Processing Mastery: We supply titanium in all standard forms—sheet, plate, bar, tube, pipe, and custom-fabricated parts—with tight tolerances and superior surface finishes.

Technical Partnership: From prototype to production run, we provide insights into machinability, heat treatment, and finishing to ensure your titanium performs as engineered.

The decision hinges on your design priorities:

Choose Commercially Pure Titanium if you need maximum corrosion resistance, easy fabrication, or biocompatibility for chemical processing, marine, or medical applications.

Choose a Titanium Alloy if you need to maximize strength, stiffness, and performance under load or heat for aerospace, high-performance automotive, or advanced industrial machinery.

Unsure which titanium grade best fits your design and budget parameters? Our technical team is ready to assist.

Contact us today for a professional consultation or to request a competitive quote for your specific titanium material needs.

This is the first one.